Advantages of the helical blade turbine meter

Written by Didier Pabois

Published on 2022-09-15

Turbine meters equipped with helical blade rotors offer a number of benefits over other commercially available technologies, making them particularly suitable for demanding applications such as crude oil or refined hydrocarbons custody transfer.

The main advantage of this type of turbine meter is its ability to tolerate large variations in fluid viscosity without significant impact on metrological performances. The measuring capacity covers a range from a few tenths of centistokes (cSt) for LPG metering applications to several hundred cSt crude oils, and a single turbine meter can easily cover a wide range, for example from 5 to 150 cSt with custody transfer linearity and repeatability.

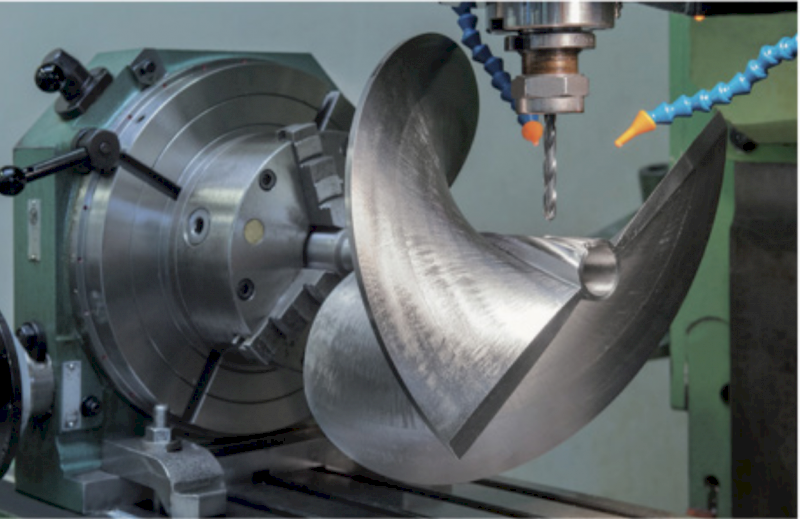

Faure Herman integrates several teams of experienced professionals in charge of design, manufacturing and final “tuning” of turbine meters to meet increasingly demanding applications. We use simulation (CFD), manufacturing (CAM), control (3D Scan) and, above all, high performance calibration meant to guarantee the expected performance . What makes Faure Herman unique is we “tune” every meter for optimum performance on the specific product viscosities the turbine will be measuring in the field. Faure Herman does not do mass produced; one size fits all meters.

This brief article defines the advantages of the helical bladed turbine meter.

As for all axial turbine meters, the helical blade turbine incorporates a rotor which rotate freely on a shaft at a speed directly proportional to the flow rate through the meter. Each revolution of the rotor represents a discreet volume of fluid and the totalization of this number of revolutions allows the determination of the volume of fluid having passed through the meter between two instances of time (start/stop).

The main advantage of helical blade turbines lies in the geometry of the rotor blades, whose basic helical profile is adapted to different configurations resulting in very low sensitivity to fluid viscosity variations. In terms of fluid mechanics, this geometry allows the fluid flow to be parallel to the surfaces of the blades (intrados and extrados) whatever the radius, and thus to minimize the effects of shear (viscosity) generating non-linearities and poor repeatability when fluid viscosity changes.

Beyond the variations in fluid viscosity, some simply induced by temperature variations, helical blade turbines can also be used for transactional metering applications of different refined products (e.g., from gasoline to jet fuel to diesel fuel) without re-configuration, but also for transferring quantities of crude oil produced by different fields, with varying properties (density, viscosity, water content …)

The Faure Herman helical blade turbines allow the transactional measurement of very low viscosity fluids such as liquefied gases (CO2, LPG ...) to much heavier fluids such as crude oils with viscosities that can exceed 500 cSt.

Beyond the linearity demonstrated by calibration, helical blade turbine meters show exceptional repeatability, even in highly viscous fluids (1000 cSt).

IMPORTANT: Although the helical blade turbine meter demonstrates remarkable accuracy and repeatability it should always be validated in the real conditions of operation, not simply in water (or some other non-specific liquid). This is true for ALL flow meters, not just the helical blade turbine meter. Faure Herman has one of the largest calibration facilities utilizing real products in the world allowing calibration, at real viscosity values, from a few liters per hour to 4500 m3/hr.

The shape of helical rotor blades reduces both the lift and drag forces induced by the fluid flow. The low lift results in a low sensitivity to fluid density variations. The low drag results in a reduced pressure drop compared to other measurement technologies except for ultrasonic and electromagnetic flow meters.

Despite the need to install helical blade turbine meters with the use of some flow conditioning devices to reduce the effects of swirl and asymmetric flow induced by the configuration of upstream piping, the small footprint & light weight of helical blade turbine meter runs make it the technology of choice for those locations with limited space and weight constraints.

A key advantage of helical bladed turbine meters over technologies utilizing electronic signal processing & manufactured pulses is their ability to be calibrated, without difficulty, utilizing a small volume prover. This results in the helical turbine meter proving with exceptional repeatability, typically ±0.02%. This advantage, combined with excellent linearity, makes the helical turbine meter an excellent master meter. Meter technologies based on electronic measurement (i.e.: Coriolis, Ultrasonic, etc.) typically require the small volume prover to be oversized (derated) resulting in significantly higher costs to the customer as a result of having to purchase a larger size prover.

The use of field replaceable sub-assemblies (measurement cartridge) allows the meter to be resized for different flow ranges over the course of its lifetime. For example, a 3” TZN flow meter is available in six (6) measurement ranges (3-20, 5-20, 7-70, 11-110, 15-150, 18-180 m3/hour). Thus, as the measurement requirements change over the years, so can the meter without requiring any hardware changes other than a different internal cartridge. The same is true for all Faure Herman meter sizes.