Applications

- Trucks Loading/Unloading through flexible hoses

- Airport refuelers

- Mobile Field Refueling

- Military Operations

Features

- Integrated electronics

- Bi-directional measurement

- Flow direction indication

- Integrated flow conditioner

- Low pressure drop

- Low power consumption

- Robust construction

- Light weight

- Designed for light products measurement

- Suitable for gasoline, kerosene and gas-oil

- Accurate measurement over 10:1 flowrate rangeability

- Calibrated on customer specified viscosities

- Saline environment-proof

- Long-term reliability

- Easy operation

- Faure Herman' almost 100 years of metering experience

Sturdiness

Our rotors are one piece elements, carved directly from a bloc of the appropriate metal for your application. The helical rotor, rounded front edge and light weight materials improve stability and linearity even in high viscosity fluids – while reducing bearing wear.

Combined with tungsten carbide bearings, we design our turbines for high performance, over a very long period of time, with minimum need for repair or maintenance.

Cartridge concept

Innovative design enables the Faure Herman flowmeter to meet your measurement for the lifetime of your facility. Our removable cartridge design with flexible flow rates allows adaptation to production changes, whether flows increase or decrease.

The design permits simple and fast maintenance, there's no need to be a metering expert.

Faure Herman technology allows your meter to meet your process condition changes without changing your existing footprint/infrastructure.

Robust CUS Bearing

Proven technology with monoblock machined rotor equipped with self-cleaning bearings secures your revenues even in harsh and polluted environments.

Outstanding Oil Calibration Laboratory

Faure Herman calibrates using multiple oils to match your process conditions, ensuring your meter’s performance along its entire operational range.

Our ISO17025 certified laboratory calibrates your meters to meet real Reynolds number conditions.

Wide and evolutive range of flowmeters

Faure Herman meters provide a variety of metering solutions adapted to improve and optimize your process management operations.

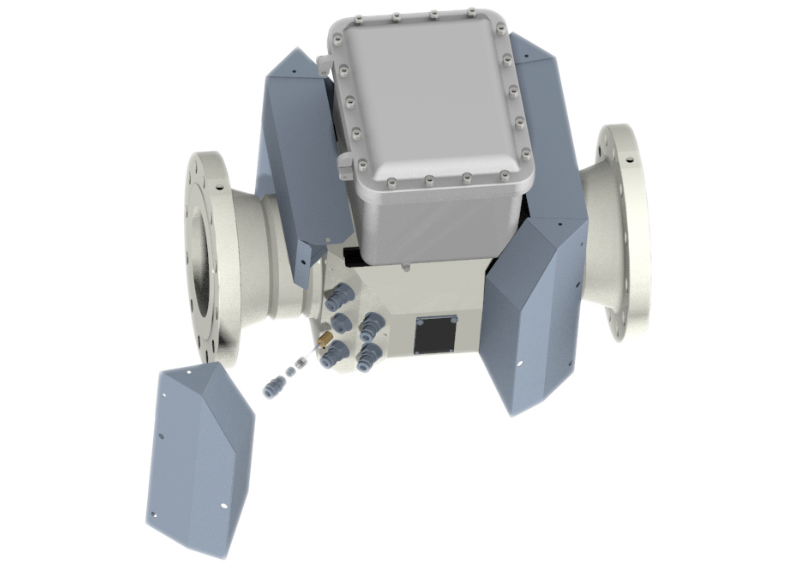

Master Meter instrumented spool piece

A complete solution putting a flow conditioner, upstream and downstream spools, and your Faure Herman Master Meter provides a compact option compared to larger provers.

Certified Meters

Faur Herman meters comply with international norms and guidelines for Custody transfer meters.

Our robust metrology expertise is fundamental to our approvals and certifications.

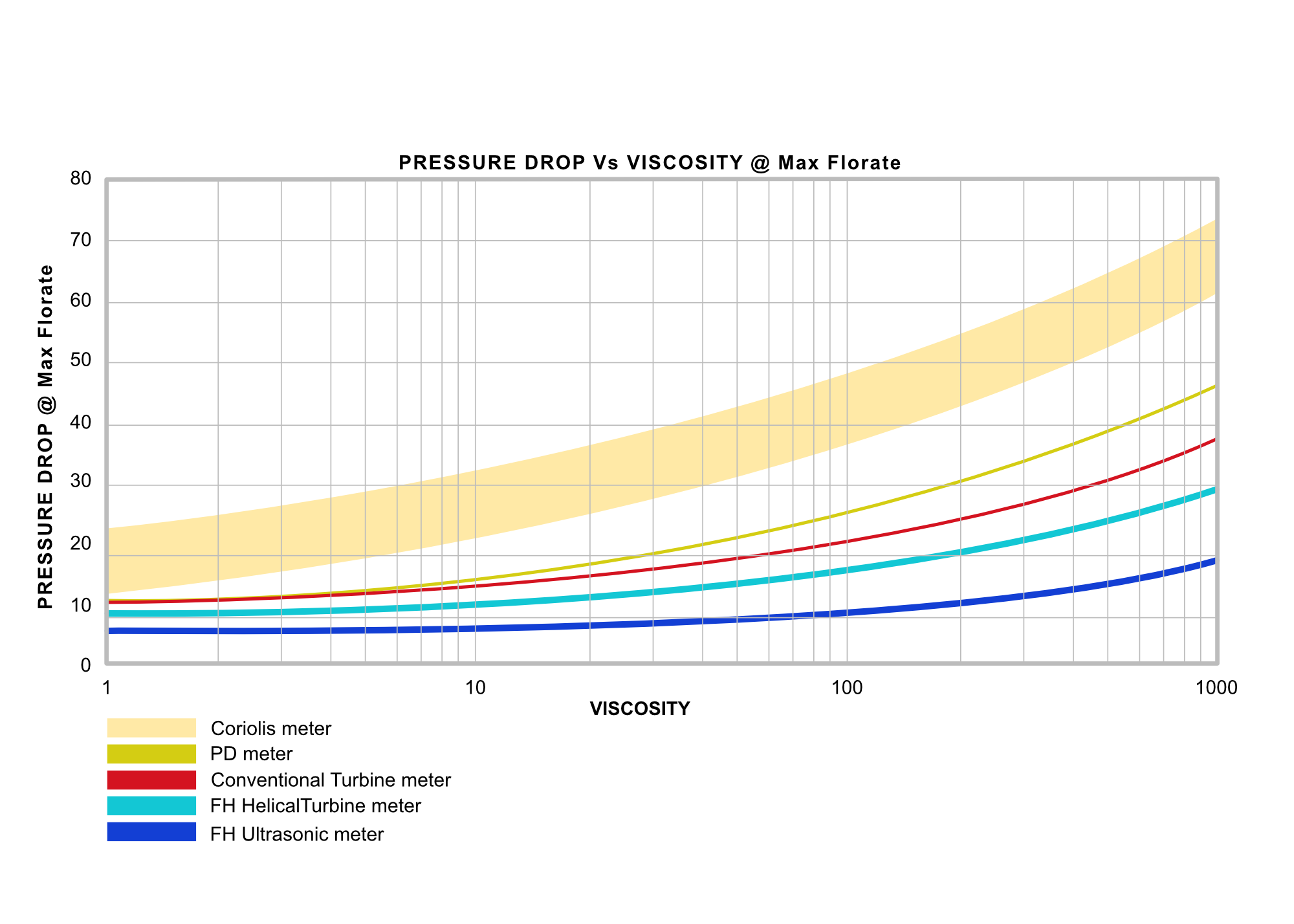

Light and compact

Faure Herman meters, both helical turbines and ultrasonic, have a minimal a footprint (both weight & dimensions) compared to Coriolis mass meters or PD meters.

Easy "no expert" maintenance

Faure Herman technologies are designed to be operated and maintained by your field personnel, reducing your potential downtime and maintenance costs.

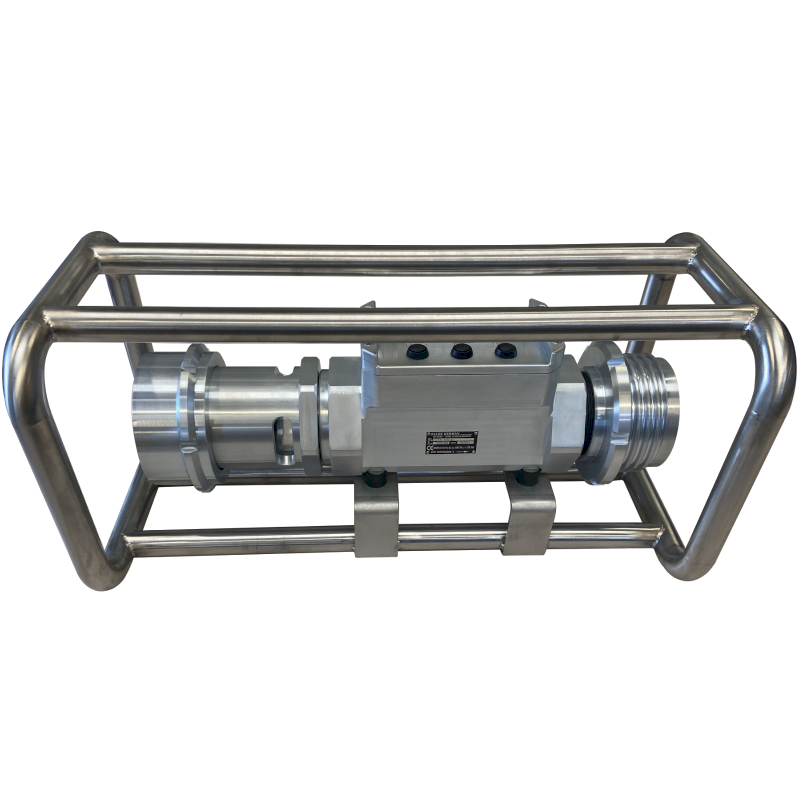

Compact and portable devices for easy military use

Designed to integrate all the metrological qualities of Faure Herman in a compact and portable "all in one" device.

Highest international quality standards

Large choice of flange types

Faure Herman offers a wide range of flanges and adapters to suit your needs.

Choice of number and position of outputs pick ups

One, two or three outputs can be customized to include local readouts and measurement verification.

Readers flexible installation

Local displays can be placed either directly on the output pick up or remotly located if this is required for ease of maintenance, security in ATR (explosives conditions) etc.

Bi-Directional Measurements

FH provides several solutions for bidirectional measurement across all our activity sectors thanks to its symmetrical rotor.

Quick response time

Thanks to customized electronics, our equipment allows particularly short response times.

Sustainability over decades

Coming from experience, it has been notices that the extreme non electronic simplicity or our equipments make them last for decades if the basic MRO program is followed.

Fine Spirits Metering Stations

Mastered technology

Long term mastered technology.

Low Pressure Drop

Thanks to low pressure requirements our various metering solutions can help you improve your operational costs in terms of energy savings.

Qualified against the most severe environmental conditions

Versatility of features allow adaptation to your processes :

-

External environment

(explosive, corrosive, harsh atmosphere)

-

Measured fluid

(corrosive, abrasive, hazardous and polluting fluid)

Light Weight

Faure Herman meets the highest requirements in terms of weight reduction.

Accuracy and repeatability

Typical accuracy is 0.15% with repeatability of < 0.04%.

Premium Master Meter accuracy is +/-0.1% with repeatability< 0.02%.

Performing factory calibration on hydrocarbons of same viscosity as your fluid characteristics ensures your meter performs in the field the same as it did in the calibration lab. This ensures accurate measurement of your revenues.

Custom calibrate / Tailor made calibration

Faure Herman provides a unique calibration service to its customers, by using the same fluid characteristics as the customer’s own fluid.

For helical turbines, Faure Herman brings an extra service by fine tuning of the rotor shape, in order to get unmatched accuracy and repeatability. These « retouche » are hand made in between two calibration runs, by specialized operators, internally trained to reproduce Faure Herman 100 year know-how.

This is what makes the difference between a good meter and a master meter.

Large Flow Rates

Flow rate capability from 0.8 to 4500 m3/h, this over a wide range of viscosity from 0.7 to 500 cSt .

Compact

Faure Herman meters can be integrated in a cold plate.

Coolant Fluid Leaks

Faure Herman designs leak detection meters for cooling systems.

Downsizing

You originally needed a maximum flow rate of 1,260 b.hr, but now, several years later, oil output has dropped below 50% of original flow…

You can go from our original 4’’ Heliflu TZN STD 100-200 to the downsized DS 100-110 model, in order to achieve a maximum flow rate of 690 bph, without changing your meter run.

This can be integrated into an existing meter skid, extending duty life without having to change existing piping.

Large Flow Rates

Air-to-Air Refueling : up to 200 000 l/h and beyond according to your needs.

Low Pressure Drop

The helical rotor concept generates less resistance to fluid’s flowing, thus reducing the associated pressure drops.

Qualified againt most severe environmental conditions

Faure Herman meters meet the DO-160 standard requirements, related to conditions such as temperature, vibration, burst pressure.

Accomodates different types of fuel

Our device can accomodate variable types of fuels that comprise bio fuels thanks to years of selecting impeller profiles and materials.

Real time information

Output Signal according to your requirements.

Accuracy for military

Performing factory calibration on hydrocarbons of same viscosity as your fluid characteristics ensures optimum performance in the field.

Low cost of ownership

Associated with interchangeability and very easy to install & maintain.

Calibration with real fluid

Faure Herman calibrates 100% of your equipments with real fuels.

Flexibility

Faure Herman meters are available in several flow ranges within a single line size, offering you the possibility of upsizing or downsizing based upon the lifecycle of your production.

This may be achieved by just changing the cartridge or the meter body, not the entire meter run. This provides significant cost savings on the metering unit.

Sturdiness

Our rotors are one piece elements, carved directly from a bloc of the appropriate metal for your application. The helical rotor, rounded front edge and light weight materials improve stability and linearity even in high viscosity fluids – while reducing bearing wear.

Combined with tungsten carbide bearings, we design our turbines for high performance, over a very long period of time, with minimum need for repair or maintenance.

Replaceable cartridge

Our TZN range of removable cartridges allow you to carry on production using a spare cartridge for replacement while the original one is sent back for repair or recalibration.

This helps you reduce downtime and save money, while providing full autonomy for your operations.

If your process conditions change, this innovative design also allows you to adapt to the new fluid and flow range, by simply changing the cartridge, without changing your existing footprint / infrastructure.

Outstanding pulse stability and repeatability

Content...

Stable & repeatable measuring meters

Faure Herman meters provide a variety of adapted flow meter solutions to improve & optimize your process management, the exceptional stability ensure optimized operations.

Miniaturized flow metering solutions

Can be integrated into cold plates.

COFRAC ILAC ISO17025 Certifications

Faure Herman delivers instrumentation fully traceable to National and international standards, thanks to its COFRAC ILAC ISO 17025 certification.

Versatile technologies

Faure Herman can supply flowmeters with different piping , material, design and accessories configurations to meet your safety, operational and performance requirements.

Reliability

Special design with minimum number of moving parts makes equipment more reliable.

Robustness for test bench & military operation

The Faure Herman meters are designed to be robust and easy to handle in the extreme conditions of military campaigns.

Rugged CUS design

Meters are often negatively affected by harsh fluids containing contaminants or solid material. This can reduce performance and significantly increase operating costs.

Faure Herman’s patented Heliflu™ TZN CUS has been designed to minimizes the measurement impact of DRA, wax, fibers, chalk, sand and other impurities in fluids :

- Tungsten carbide shaft and bearings with special shape for auto-cleaning

- Monobloc titanium rotor

The CUS design will maintain high accuracy, even with heavy crude oils and will provide extended service life of your meter, in those harsh conditions.

ROBUSTNESS

The Faure Herman meters are designed to be robust and resistant to specific sea water process conditions.

Full bore design

The Faure Herman ultrasonic flowmeter is a full bore body design.

There are no obstacles or moving parts to generate any pressure drop.

Superior to other technologies

Evolutive design allowing Faure Herman flowmeter to meet your needs in terms of measurement ranges and process connection.

Miniaturization of meter components

Faure Herman is able to provide compact meters to meet your footprint and performance requirements.

High level of performance is reached thanks to know-how in impeller designing and manufacturing.

Reliability of embedded equipment

Faure Herman is recognized by major Aerospace firms as having the ability to provide the highest quality, most reliable embedded flowmeters.

Bi-directional conception

Due to it's conception & technologie, Ultrasonic flowmeter allows flow measurement in both flow directions.

Transducers replaceable under pressure conditions